A multidisciplinary team of scientists from the University of Coimbra (UC) developed materials to make 4D printing (four dimensions) sustainable and ecological, based on cellulose produced by bacteria. The project opens doors to countless applications, from medicine to transport and the textile sector.

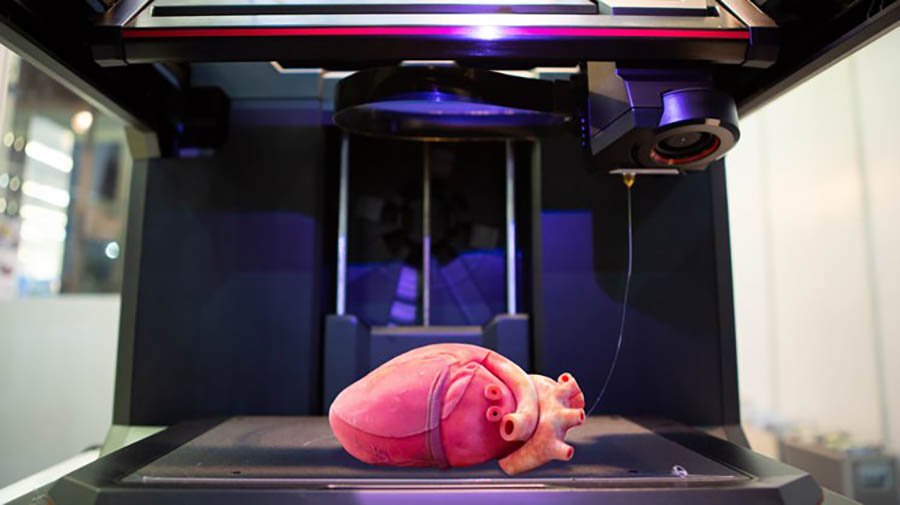

4D printing arises from 3D printing, adding the time dimension, allowing the printing of intelligent three-dimensional objects, that is, objects that, with time and through external stimuli, such as temperature, light or pH, among others, change shape.

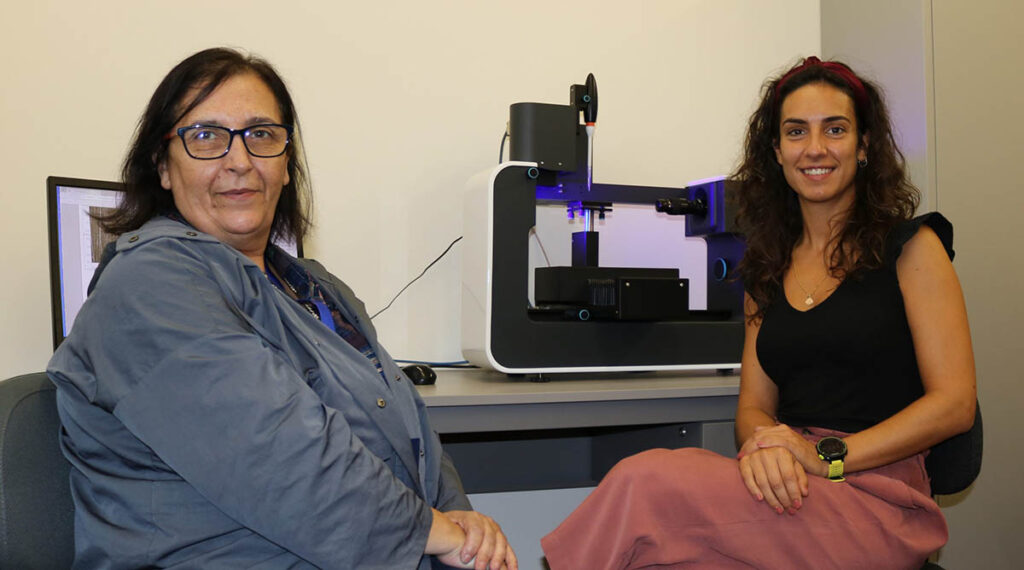

From 3D to 4D printing: can bacterial cellulose make the bridge? This was the starting point for the development of the project, led by Ana Paula Piedade, researcher and professor at the Faculty of Science and Technology of the University of Coimbra (FCTUC).

Financed in the amount of 250 thousand euros, by the Foundation for Science and Technology (FCT) and by European funds (COMPETE 2020), the project has the collaboration of the Polytechnic Institute of Leiria (IPL).

In order to answer the question, the team decided to use the bacteria as “living tools” in the production of cellulose, a highly versatile natural polymer. As in any company, the recruitment and selection process is a fundamental step. Thus, the Environmental Microbiology team at the UC that is part of the project began by identifying a group of bacteria and selecting those that showed more capacity for the function. To do so, it resorted to the Collection of Bacteria Cultures of the University of Coimbra (UCCCB).

“Through genomic analysis, the microbiology group identified the bacteria that have genes for the production of cellulose. A group of bacteria was then chosen, which were later characterized and tested, and two strains were selected», explains Ana Paula Piedade.

Once this process was completed, the bacteria “factory” began working until the necessary cellulose was obtained to produce a material that would enable 4D printing. «The celluloses obtained were mixed with dissimilar polymers (with different properties of each of the celluloses) and, from there, we produced the biocomposites and developed the filaments suitable for 4D printing», describes the researcher from CEMMPRE – Center for Mechanical Engineering, Materials and Processes – from FCTUC.

Counted like that, it seems like it was a simple process, but no. The team had to carry out several studies and face many complex challenges. The greatest of them, reports Ana Paula Piedade, was, and continues to be, achieving the «reversibility of the material, that is, guaranteeing that the same material that takes different forms through external stimuli is able to return to the format by itself. original. 4D technology allows the material to transform and then return to its original shape».

Overcoming the various obstacles and challenges, different types of objects were successfully printed, opening doors to a wide range of applications. For example, producing 'devices that can operate in places where there is no electricity, devices capable of changing shape depending on the mechanical demand they have, smart clothes for high competition athletes, which regulate perspiration depending on the ambient temperature, biomedical devices, finally, there is a “world of possibilities”», points out the project leader.

The technology now developed is sustainable and low-cost, because the bacteria only need “food” (which can be, for example, food waste) to produce cellulose, and it is environmentally friendly: «97% of the material used stays in the piece itself. that is printed, that is, the waste produced is minimal and, even so, this waste can be used to produce more filaments», underlines Ana Paula Piedade.

Furthermore, both the composite material and the cellulose are completely biodegradable and biocompostable. Another great advantage of using bacteria is the fact that they produce pure cellulose, unlike, for example, cellulose obtained from trees, which requires several purification treatments.

The FCTUC scientist further clarifies that these bacteria used to manufacture cellulose are not pathogenic. “On the contrary, they are strong allies to make 4D printing possible. We cannot forget that bacteria are the result of millions of years of evolution, they learn and adapt».

The next phase of the research will focus on designing structures for specific applications, namely the design of devices that can take advantage of this 4D effect. “We are going to explore different approaches for manufacturing 4D devices, as it is necessary to think very carefully about how we are going to print, define the geometry of what will be printed and optimize processes that guarantee the 4D effect”, he concludes.

Comments