A PhD student at the University of Algarve developed from scratch a 3D Printer, which allows the creation of three-dimensional objects from a design made on a computer.

A PhD student at the University of Algarve developed from scratch a 3D Printer, which allows the creation of three-dimensional objects from a design made on a computer.

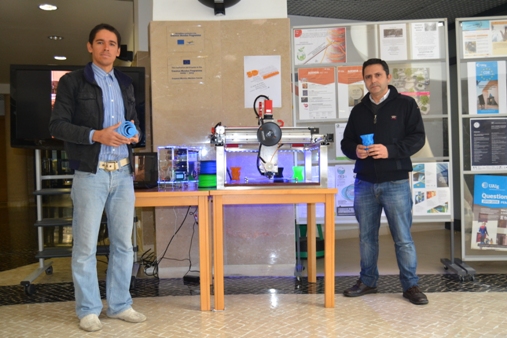

Aldric Négrier had already won the “Ideias em Caixa” contest, from CRIA, in 2010, with a “DriveMyPhone” project, which allows the remote control of mechanical and electronic devices, through an application for Smartphone. And it was while developing this idea that he thought about creating this printer.

For Aldric “in the Algarve there is a gap with regard to the market for rapid prototyping services”. A gap which he realized when he was trying to develop a high-fidelity prototype of his DriveMyPhone and found some difficulties in accessing machines that would allow him to manufacture the chassis parts with quality.

“With this machine I can quickly manufacture three-dimensional models and, in this way, move forward with the process of interactive improvements, through the functionality of the 3D printer”, he explained.

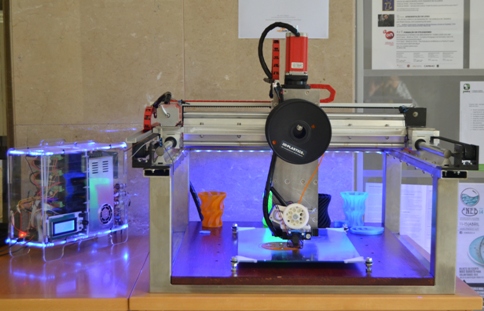

3D printers are used in the most diverse areas, from industrial design, the automotive and aerospace industry, dentistry and the arts, among others. In the case of the “Made in Algarve” apparatus, the «Fused Filament Fabrication» technology was used, fusing three machines into one, namely a 3D printer, a CNC milling machine and a laser cutting machine, all of them made at UAlg.

3D printers are used in the most diverse areas, from industrial design, the automotive and aerospace industry, dentistry and the arts, among others. In the case of the “Made in Algarve” apparatus, the «Fused Filament Fabrication» technology was used, fusing three machines into one, namely a 3D printer, a CNC milling machine and a laser cutting machine, all of them made at UAlg.

“Print materials can be different types of plastics. With the CNC, also controlled by a computer, we can use other types, such as wood, aluminum and polymers, submitting them to the action of the machine to be processed», according to Aldric Négrier. This laser cutting functionality will allow you to cut and engrave designs in various materials with great speed and accuracy.

The creator of the printer believes that this machine will enable the creation of products from different materials very quickly, on a small scale and with low investment.

«Although the initial objective was not commercialization, today I am able to build similar and customized machines, responding to the requirements of each client. A more attractive market opportunity could be offering prototyping services to research laboratories, entrepreneurs and companies that want to develop prototypes», summarized Aldric Négrier.

Comments